Each year, employees miss work and potential wages

due to work-related musculoskeletal disorders (MSDs). According to the Bureau

of Labor Statistic (BLS), 335,390 American workers experienced MSDs serious

enough to require time off work in 2007.

In fact, injuries to the muscles and skeleton are

among the most common lost time illnesses and injuries in virtually every

industry.

Musculoskeletal disorders occur when there is a

mismatch between what your job requires you to do and what your body is capable

of doing. MSDs can affect worker in job activities across many diverse

workplaces and tasks.

The Institute of Medicine estimates that the

economic burden of MSDs in the workplace, as measured by compensation costs,

lost wages, and lost productivity, are between $45 and $54 billion annually. Historically,

overexertion, one form of MSDs, is the number one cause of workplace injury.

In 2007, there were 1,2 million MSD cases requiring

days away from work in private industry out of 4 million total recordable

cases. Of these, 335, 390 cases required an average of nine days away from work,

two more days than the average for all days away from work cases.

Because of statistics like these, ergonomics has

become an important and serious issue for industry.

The term “ergonomic” is derived from two Greek

words: “erg” meaning work and “nomas” meaning natural laws.

Basically, ergonomics is the science of adjusting

job conditions, equipment, and tasks to match the body’s natural ways of

functioning.

The goal of ergonomics is to prevent illness and

injury, assure high productivity, and promote satisfaction in the workplace.

In the absence of a federal ergonomics standard, the

Occupational Safety and Health Administration (OSHA) has addressed ergonomics

in the workplace under the authority of section 5 (a)(1) of the Occupational

Safety and Health Act.

This section is referred to as the General Duty

Clause and requires employers to provide work and a work environment free from

recognized hazards.

Many employers have realized that the implementation

of an ergonomics program is in their best interest for the reduction of

injuries and illnesses.

An ergonomics program addresses some basic elements

such as employers and employee responsibilities, hazards identification and

information, job hazard analysis and control, training, medical management,

records, and programs evaluation.

Your company’s ergonomics programs is designed to

help keep you healthy, productive and motivated while making your working life

as enjoyable as possible.

Your company can express its commitment in a variety

of ways. These include holding employee meeting to discuss ergonomics operational

goals and priorities that are firm, achievable, and in line with cost

reduction, productivity, and quality initiatives.

In addition, your employer may commit resources to

training, administrative needs, expertise, and ergonomics improvements or issue

policy statements that define support and cooperation from management,

supervision, and employees.

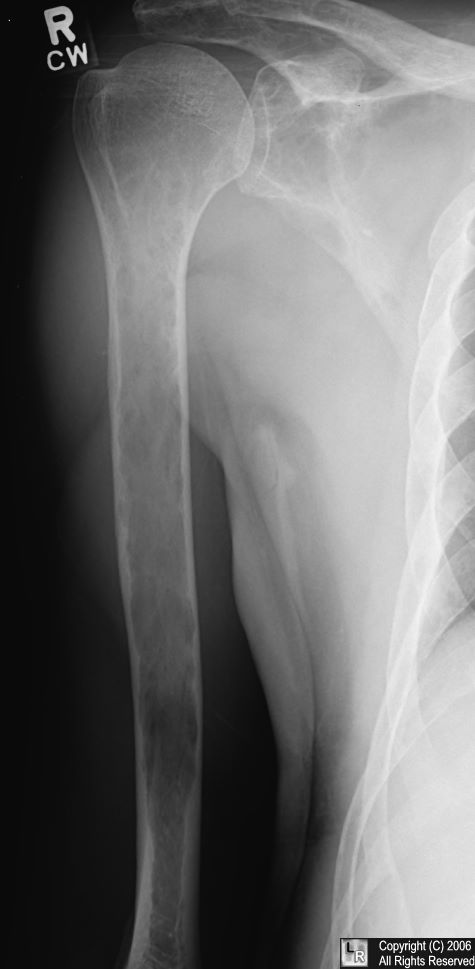

Musculoskeletal Disorders (MSDs) definitions: Are

disorders of the muscles, ligaments, tendons, cartilage, joints, nerves, or

spinal discs that have been diagnosed by physical exam, medical history, or

specific medical test.

They typically result from gradual or chronic development,

as opposed to an acute event or injury caused by, for example, a slip or fall.

MSDs like carpal tunnel syndrome have very distinct signs and symptoms. Other disorders,

such as lower back pain, are simply defined by the location of the pain.

To better understand ergonomics, you should be

familiar with the major parts of the musculoskeletal system:

Ø Bones:

Provide structural support and are connected to one another at joints, which

allow movement between body segments.

Ø Muscles:

Contract and shorten, causing movement, just contract to provide stability. The

respiratory and circulatory systems supply nutrients and oxygen necessary for movement

of muscles.

Ø Ligaments

and tendons: ligaments connect bone to bone and provide stability at the

joints, while tendons attach muscle to the bone.

Ø Cartilage:

Provides the joints with low friction surface that help with movement.

Ergonomics Awareness

Recognizing the early signs and symptoms of injuries

to the muscles and skeleton and reporting them as soon as possible is very

important. A health care provider (HCP) can observe the signs. Symptoms,

however, are subjective and a patient needs to report them to HCP.

Signs of injury to the muscles and skeleton include

redness or loss of color, swelling, loss of function, deformity such as a lump,

decreased range of motion, and decreased grip strength.

Symptoms are your body’s way of warning you that you

may be developing an injury. Symptoms of injury to the muscles and skeleton can

vary in severity, depending on the amount of your exposure.

Eventually the symptoms become more severe as

exposure continues and will appear even after rest. The pain may increase to a

point where it becomes difficult to perform your work or even to a point where

you are unable to perform any physical work activities.

Examples of symptoms of injury to the muscles and

skeleton include numbness, burning, tingling, aching, pain or soreness,

stiffness, and cramping.

Early reporting is vital in preventing or minimizing

injury to the muscles and skeleton. As an employee, you must feel free to

report any signs or symptoms of physical discomfort as soon as possible to your

supervisor or other personnel, such as a plant nurse or HCP.

Employers can also gather information by conducting

symptoms surveys and interviews.

Risk Factors

The OSHA has identified a high rate of injury among

workers in various industries. It is impossible to determine the exact weight

lifted or the number of repetition that will either cause or prevent injury.

However, establishing a systematic approach to

address such issues as repetition, excessive force, awkward posture, and heavy

lifting reduces the chance that you may ne injured.

Identifying risk factors in the workplace, before

injuries to the muscle and skeleton are discovered, is an important step in

keeping you healthy.

Your employer can use several methods to detect risk

factors, such as interviews with workers and supervisors, and walk-through

observations of the workplace.

A more formal approach would be to use a

standardized checklist to evaluate job tasks against risk factors.

There are many different types of risk factors for

injuries to the muscle and skeleton, some of which are not entirely

work-related.

Risk factors for work-related musculoskeletal disorders

are cumulative and can include off-work activities as well. Physical limitations,

previous injuries, or existing health problems can contribute to increased

risk.

It is often difficult to determine the impact that

work activities versus non-work activities (sport or medical conditions such as

rheumatoid arthritis, diabetes, and thyroid conditions) have on the disorder.

For example, in the general population, non-work

causes of lower back pain are probably more common than workplace causes.

When jobs have risk factors in combinations and high

levels, the risk of developing a musculoskeletal disorder will increase. The level

of risk also depends on the intensity, frequency, and duration of exposure. Examples

of risk factors include repetitive, forceful, or prolonged exertion and

pushing, pulling, or carrying heavy objects.

Risk factors (Actions)

·

Repetitive, forceful, or prolonged

exertion

·

Frequent or heavy lifting

·

Pushing, pulling, or carrying of heavy

objects

·

Prolonged awkward postures

·

Work in the cold

·

Insufficient pauses and rest breaks for

recovery

Risk factors (Conditions)

·

Contact stresses

·

Machine-paced work

·

Stress

·

Unfamiliar or unaccustomed work

·

Vibration

Gathering data is a vital step toward the

identification of a problem. Checklists can be used to provide the initial

identification of a job or task which may put a worker at risk for developing

an injury to the muscles or skeleton.

It is important to understand that the checklist

findings must be viewed as a whole to determine if the individual problems

suggest the same underlying root cause.

Control Methods

Many employers provide engineering controls, such as

lift-assist equipment, that go unused or under-used as the employees hurry to

complete their tasks.

Engineering controls reduce or eliminate the

condition by modifying or redesigning workstations, environmental conditions,

tools and equipment, processes, or materials.

For instance, a situation was reviewed in the

electrical industry, where tasks included hammering, crimping, wrapping,

winding, soldering, painting, and various electric motor assemble operations.

Problem: risk factor involved in these types of

tasks included repetitive and forceful exertions, awkward postures, and contact

stress. Workers were found to suffer from upper limb and neck illnesses and

injuries.

Solutions: included raised standing surfaces, a

modified mallet handle, and low force clamps. Job rotation, training programs,

and early reporting were also needed.

Workstation should be adjustable to fit your body. Furniture

and equipment should be positioned to prevent excessive twisting, reaching, and

leaning.

Eyes: Computer monitors should be placed so that the

top of the screen is just below eye level.

Arms and back: Chair should have adjustable armrests

to take the load off your neck and shoulders. Chair should have back rests that

fit your back.

Knees and feet: Chair should ne adjustable to allow

your knees to be bent at a right angle. Chair should be adjustable to allow

your feet to rest flat on the floor. Footrest may be used.

When your finger are on the keyboard, your wrist

should be straight in a neutral position with the upper arm vertical and the

forearm at a 90 degree angle to the upper arm.

Your shoulders should be relaxed and your elbows

close to your sides. Reclining and reaching should also be avoided.

When using the mouse, you should be able to maintain

the correct arm and wrist position. The mouse should be at the same levels as

the keyboard and the same distance from your body as the keyboard.

Administrative controls are changes in the workplace

that adjust work practices, procedures, and management policies.

Specific examples include rest breaks, alternative

tasks, slower work pace, redesign of work methods, and employee rotation.

Consider his example of an office work setting. Management

reviewed an office environment that involved primarily data entry and tasks

involving video display units.

Problems: risk factors identified from these tasks

included repetitive exertions, awkward postures, glare, and poor illumination. Personnel

experienced problems with upper limbs, neck, back, and eyestrain.

Solutions: included reduction glare and improving

workstation design. A vision test program and a rest break schedule where also

suggested.

You would use personal protective equipment (PPE),

such as gloves, to reduce vibration and prevent injury.

Always use engineering control s first if possible,

followed by administrative controls. Use PPE only as a last resort.

Studies show that wearing a back belt does not

reduce injury rates or the number of lost work days. However, wearing a back

belt and having training on lifting techniques may reduce lost work days for

people who have had lower back pain in the past.

Because musculoskeletal disorders involving the back

are among the most costly occupational injuries, it is important to review back

safety and some basic techniques for prevention of back injuries.

These techniques include good posture, proper

lifting, and the practice of basic exercises, such as stretching.

To evaluate your posture, stand with your back

against a doorframe and slip your hand between the doorframe and the small of

your back. Your hand should slide in easily and slightly touch your back and

the doorframe.

When possible, plan jobs to avoid unnecessary

lifting. Improper lifting, especially when combined with twisting, is the most

common way to injure your back.

Correct posture: Place feet firmly apart with one

foot forward for stability. Bend at the knees (not at the waist) and keep your

back as close to vertical as possible.

Incorrect posture: two of the most common mistake

made when lifting are bending at the waist instead of the knees and holding the

load too far out in front of you.

When lifting, tighten your stomach muscle as soon as

you lift to support your spine, breathing out as you lift. Do not hold your

breath.

Remember t use your leg muscles instead of your back

muscle to lift the load. Do not twist your body while lifting and keep the load

close to your body as you lift.

The best path to a healthy back is to control your

weight, exercise, and reduce back stress caused by lifting or poor posture.

Excessive upper body weight such as potbelly

contributes to poor back posture and back pain because of the added stress

placed on the components of the back.

A regular exercise program that includes flexibility

and strengthening exercises can help prevent injury or re-injury to your back.

Consult your healthcare provider before beginning an exercise program.

Remember to report signs, symptoms, and hazards of

MSDs and make recommendations on appropriate ways to control them. Ways to make

these recommendations include e-mail, letters, and notes to your supervisor.

Recommendations can also be made verbally through an

employee representative or by serving on health and safety committees. Always follow

applicable workplace procedures and safety and health rule.

Summary:

Employers are not the only ones with specific

responsibilities. You, as an employee, have an important role also.

Your responsibilities include:

v Recognizing

the signs and symptoms of MSDs and the value of reporting them early

v Identifying

MSD hazards in your job

v Knowing

how to use and evaluate the control measures your employers implements, and

v Working

in ways that will reduce the risks in your job

Retrieved from: http://berryplastics.skillport.com/skillportfe/main.action?content=myprogressNew